Count six sensors to make industrial robots smarter and more interactive

Count six sensors to make industrial robots smarter and more interactive

(Summary description)With the continuous development of industrial robot technology, robots are no longer just tools to carry heavy objects. The application of sensor technology has made industrial robots much smarter. Sensors have added feelings to the robots, it provides the basis for the work of high precision intelligent robot. Here's a look at the six most commonly used sensors in today's industrial robotics.

1.2-d vision sensor

Two-dimensional vision sensor is mainly a camera, it can complete the detection of object motion and positioning and other functions, two-dimensional vision sensor has been appearing for a long time, many intelligent cameras can coordinate the industrial robot's course of action and adjust the robot's behavior according to the received information.

2.3-d vision sensor

With the development of 3D vision sensor, 3D vision system must have two cameras shooting at different angles, so the 3D model of object can be detected and recognized. Compared with two-dimensional vision system, three-dimensional sensor can show things more intuitively.

3.Force torque sensor

Torque sensor is a kind of sensor that can let the robot know the force. It can monitor the force on the robot arm and guide the next action of the robot according to the data analysis.

4.Collision detection sensor

The biggest requirement of industrial robot, especially cooperative robot, is safety. To build a safe working environment, we must let the robot recognize what is not safe. The use of a collision sensor allows the robot to understand what it is touching and send a signal to pause or stop the robot's motion.

5.Security sensors

Unlike the above collision detection sensors, the use of safety sensors allows industrial robots to sense the presence of objects around them, and the presence of safety sensors prevents the robot from colliding with other objects.

6.Other sensors

In addition to these there are many other sensors, such as welding seam tracking sensors, to do a good job of welding, you need to be equipped with such a sensor, as well as touch sensors and so on. Sensors bring a variety of senses to industrial robots that help them become more intelligent and work with greater accuracy.

- Categories:2016 Year

- Author:

- Origin:

- Time of issue:2016-06-07 15:27

- Views:0

With the continuous development of industrial robot technology, robots are no longer just tools to carry heavy objects. The application of sensor technology has made industrial robots much smarter. Sensors have added feelings to the robots, it provides the basis for the work of high precision intelligent robot. Here's a look at the six most commonly used sensors in today's industrial robotics.

1.2-d vision sensor

Two-dimensional vision sensor is mainly a camera, it can complete the detection of object motion and positioning and other functions, two-dimensional vision sensor has been appearing for a long time, many intelligent cameras can coordinate the industrial robot's course of action and adjust the robot's behavior according to the received information.

2.3-d vision sensor

With the development of 3D vision sensor, 3D vision system must have two cameras shooting at different angles, so the 3D model of object can be detected and recognized. Compared with two-dimensional vision system, three-dimensional sensor can show things more intuitively.

3.Force torque sensor

Torque sensor is a kind of sensor that can let the robot know the force. It can monitor the force on the robot arm and guide the next action of the robot according to the data analysis.

4.Collision detection sensor

The biggest requirement of industrial robot, especially cooperative robot, is safety. To build a safe working environment, we must let the robot recognize what is not safe. The use of a collision sensor allows the robot to understand what it is touching and send a signal to pause or stop the robot's motion.

5.Security sensors

Unlike the above collision detection sensors, the use of safety sensors allows industrial robots to sense the presence of objects around them, and the presence of safety sensors prevents the robot from colliding with other objects.

6.Other sensors

In addition to these there are many other sensors, such as welding seam tracking sensors, to do a good job of welding, you need to be equipped with such a sensor, as well as touch sensors and so on. Sensors bring a variety of senses to industrial robots that help them become more intelligent and work with greater accuracy.

Latest News

Discuss and jointly build | Fujian WIDE PLUS and experts from Northeast Process Automation Design Committee lead the localization process

More services please pay attention to Fujian WIDE PLUS won the Fuzhou Mawei High-tech Park "Harmony Cup" employee tug-of-war invitational third public number

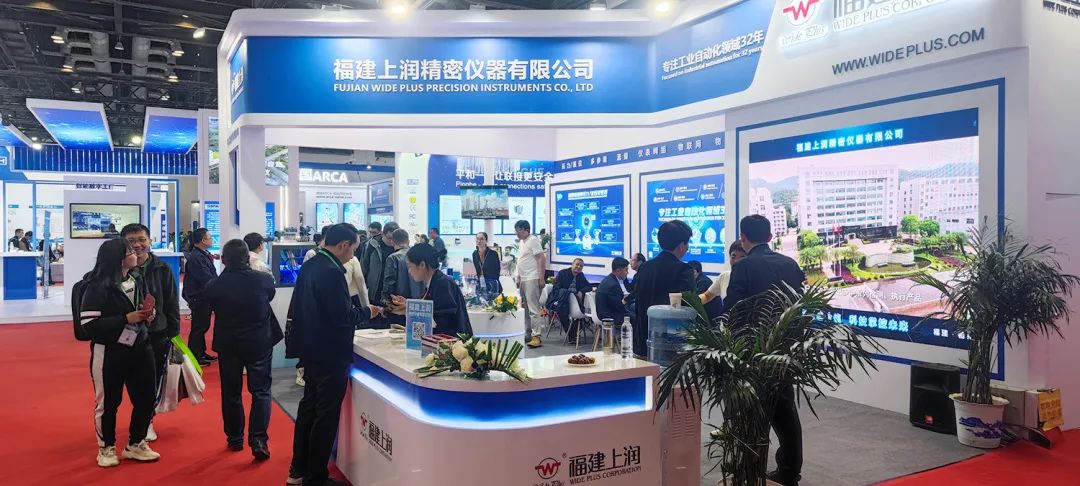

The 31st China International Measurement Control and Instrumentation Exhibition was successfully concluded, and Fujian WIDE PLUS harvested a lot

The main business of Fujian WIDE PLUS Precision Instrument Co., Ltd. involves the R&D and manufacturing of pressure, flow, temperature, liquid level, photoelectricity, water quality and other parameter sensors as well as instrumentation tubes and valves in the industrial field; the R&D and manufacturing of high-precision automation equipments; high-precision mechanical machining; and the products and overall solutions of the city's intelligent water affairs.

Fujian WIDE PLUS Precision Instrument Co., Ltd.

ADD:No.16, Xingye West Road, Mawei High-tech Zone,Fuzhou,Fujian China

Email:info@wideplus.com

Toll-free technical service number:

400-887-6339

Follow Us On

Copyright © 2023 Fujian WIDE PLUS Precision Instrument Co., Ltd.

闽ICP备05035149号-1 Powered by saa