Fujian WIDE PLUS Precision Manufacturing helps open "China's sky Eye", adhere to more than 20 years of deep cultivation to interpret the "craftsman spirit"

Fujian WIDE PLUS Precision Manufacturing helps open "China's sky Eye", adhere to more than 20 years of deep cultivation to interpret the "craftsman spirit"

(Summary description)In September last year, the world's largest single-aperture and most sensitive radio telescope with China's independent intellectual property rights was officially inaugurated in Pingtang County, Guizhou. Dubbed "China's Eye of heaven," the telescope has attracted attention for its ability to pick up electromagnetic signals from 13.7 billion light-years away. The "sky eye" used to receive the signal antenna in the "centripetal joint truss structure axis", is from Fujian WIDE PLUS Company.

Last a year, nearly 20,000 parts are not the same

The lollipop shaped metal piece, about 30 cm long, is the "axial joint truss structure shaft" made by WIDE PLUS Company, and there are more than 19,000 such accessories on the "Sky Eye".

Amazingly, none of the nearly 20,000 accessories are exactly the same. The antenna is crucial to the sensitivity and resolution of the telescope, and the related accessories are manufactured with no room for error. As long as there is a deviation of 0.1 mm, the error of several hundred meters or more will be generated when receiving the signal. The antennas are distributed radially around hundreds of times, so these 'lollipops' have 3 to 5 threaded openings for mounting the upper bracket. The telescope is a curved line, and installed on the ground, there is a drop itself, so the thread on each accessory and the perpendicularity of the plane are not the same, need to be manufactured separately, its workload and difficulty is huge. In March 2015, WIDE PLUS Company organized a group of excellent technical backbone to overcome the difficulties, and it took more than a year to complete the task in April 2016. This project is the heaviest and most complex test that we have encountered in the past 20 years since the establishment of WIDE PLUS, but we did it!

Excellence in small links can also lead to innovation

How on earth are these more than 19,000 accessories completed?

In the field of machining, everyone tries to do their own responsible process to the extreme. Small innovations in each process can eventually lead to qualitative changes and even theoretical innovations in technology.

We create a table for each part, design a three-dimensional drawing, and then use the equipment to program, process, and finally inspect. Since the Angle of each thread opening is different, and the Angle deviation of the antenna needs to be kept within 0.01°, the detection error is the most difficult place in the entire process. "General equipment is difficult to detect, so we innovatively use three-dimensional detection methods to ensure accuracy based on the plane."

When each part goes through each process, it has the same processing number as the "ID card", so as to clarify the specific responsible person, we must verify and confirm the drawings and procedures, and can not make a mistake. It is with such a strict process flow, the whole batch of accessories are completely fired, and the antenna installation is "seamless". In the production process, only two slightly defective waste products were detected.

Because of the large quantity and complex technology. Even with nearly 30 technicians working in 24-hour shifts, they are in danger of not being able to finish on time. Deputy director of the engineering Department, senior technician Huang Wenming bold innovation, improve the processing technology, the original processing of 5 to 6 will wear the tool performance to be able to process 50 or 60, so that the processing efficiency is greatly improved.

Do not forget the original intention to look forward to a more powerful precision manufacturing team

The successful completion of this major project depends on the fact that we have accumulated more than 100 technicians over the past 20 years. Over the years, the road of precision manufacturing of WIDE PLUS has gone a little "lonely".

"Precision manufacturing is not just 'workers', but technical talents, both proficient in light, electricity, mechanics and other disciplines, but also need to have enough patience and perseverance to cope with the long and boring processing process." To train a qualified technician for at least 7 years, the cost is equivalent to 20 software engineers. At present, China's high precision manufacturing talents are in a state of non-shortage.

Mr. Huang Xunsong, chairman of WIDE PLUS Company, said that if the country wants to achieve intelligent manufacturing, the Internet of Things is the key, and there is no sensor based on precision manufacturing, it is equivalent to building a highway without a car, and it cannot eventually realize the connection of things. There are 30,000 kinds of sensors needed for the global Internet of Things, and China can only manufacture 1,500 kinds. At present, Fuzhou gathers a large number of Internet of Things enterprises, the strength of 6 months ahead of the country. It is hoped that more capable enterprises can join the field of precision manufacturing and occupy new heights for China's

- Categories:2017 Year

- Author:

- Origin:

- Time of issue:2017-08-08 14:12

- Views:0

In September last year, the world's largest single-aperture and most sensitive radio telescope with China's independent intellectual property rights was officially inaugurated in Pingtang County, Guizhou. Dubbed "China's Eye of heaven," the telescope has attracted attention for its ability to pick up electromagnetic signals from 13.7 billion light-years away. The "sky eye" used to receive the signal antenna in the "centripetal joint truss structure axis", is from Fujian WIDE PLUS Company.

Last a year, nearly 20,000 parts are not the same

The lollipop shaped metal piece, about 30 cm long, is the "axial joint truss structure shaft" made by WIDE PLUS Company, and there are more than 19,000 such accessories on the "Sky Eye".

Amazingly, none of the nearly 20,000 accessories are exactly the same. The antenna is crucial to the sensitivity and resolution of the telescope, and the related accessories are manufactured with no room for error. As long as there is a deviation of 0.1 mm, the error of several hundred meters or more will be generated when receiving the signal. The antennas are distributed radially around hundreds of times, so these 'lollipops' have 3 to 5 threaded openings for mounting the upper bracket. The telescope is a curved line, and installed on the ground, there is a drop itself, so the thread on each accessory and the perpendicularity of the plane are not the same, need to be manufactured separately, its workload and difficulty is huge. In March 2015, WIDE PLUS Company organized a group of excellent technical backbone to overcome the difficulties, and it took more than a year to complete the task in April 2016. This project is the heaviest and most complex test that we have encountered in the past 20 years since the establishment of WIDE PLUS, but we did it!

Excellence in small links can also lead to innovation

How on earth are these more than 19,000 accessories completed?

In the field of machining, everyone tries to do their own responsible process to the extreme. Small innovations in each process can eventually lead to qualitative changes and even theoretical innovations in technology.

We create a table for each part, design a three-dimensional drawing, and then use the equipment to program, process, and finally inspect. Since the Angle of each thread opening is different, and the Angle deviation of the antenna needs to be kept within 0.01°, the detection error is the most difficult place in the entire process. "General equipment is difficult to detect, so we innovatively use three-dimensional detection methods to ensure accuracy based on the plane."

When each part goes through each process, it has the same processing number as the "ID card", so as to clarify the specific responsible person, we must verify and confirm the drawings and procedures, and can not make a mistake. It is with such a strict process flow, the whole batch of accessories are completely fired, and the antenna installation is "seamless". In the production process, only two slightly defective waste products were detected.

Because of the large quantity and complex technology. Even with nearly 30 technicians working in 24-hour shifts, they are in danger of not being able to finish on time. Deputy director of the engineering Department, senior technician Huang Wenming bold innovation, improve the processing technology, the original processing of 5 to 6 will wear the tool performance to be able to process 50 or 60, so that the processing efficiency is greatly improved.

Do not forget the original intention to look forward to a more powerful precision manufacturing team

The successful completion of this major project depends on the fact that we have accumulated more than 100 technicians over the past 20 years. Over the years, the road of precision manufacturing of WIDE PLUS has gone a little "lonely".

"Precision manufacturing is not just 'workers', but technical talents, both proficient in light, electricity, mechanics and other disciplines, but also need to have enough patience and perseverance to cope with the long and boring processing process." To train a qualified technician for at least 7 years, the cost is equivalent to 20 software engineers. At present, China's high precision manufacturing talents are in a state of non-shortage.

Mr. Huang Xunsong, chairman of WIDE PLUS Company, said that if the country wants to achieve intelligent manufacturing, the Internet of Things is the key, and there is no sensor based on precision manufacturing, it is equivalent to building a highway without a car, and it cannot eventually realize the connection of things. There are 30,000 kinds of sensors needed for the global Internet of Things, and China can only manufacture 1,500 kinds. At present, Fuzhou gathers a large number of Internet of Things enterprises, the strength of 6 months ahead of the country. It is hoped that more capable enterprises can join the field of precision manufacturing and occupy new heights for China's manufacturing industry.

Latest News

Discuss and jointly build | Fujian WIDE PLUS and experts from Northeast Process Automation Design Committee lead the localization process

More services please pay attention to Fujian WIDE PLUS won the Fuzhou Mawei High-tech Park "Harmony Cup" employee tug-of-war invitational third public number

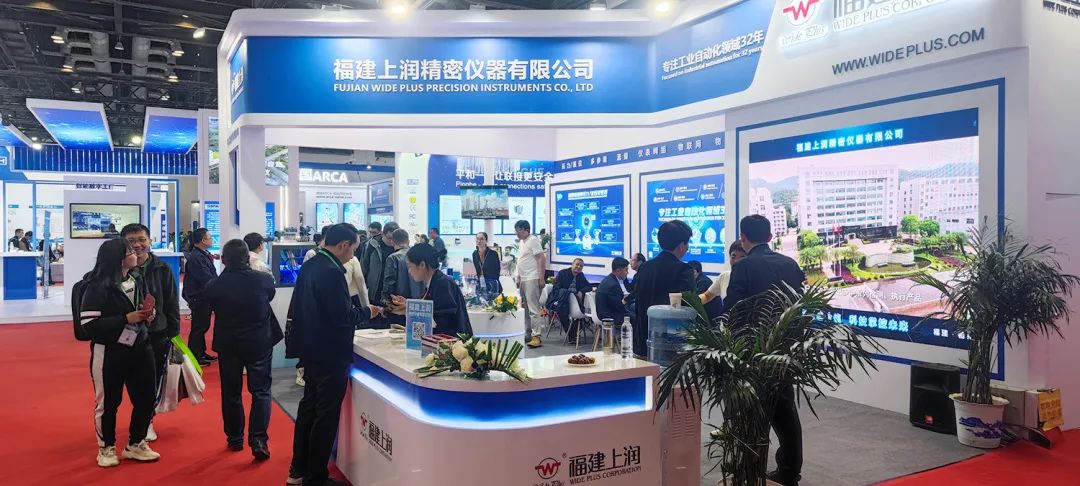

The 31st China International Measurement Control and Instrumentation Exhibition was successfully concluded, and Fujian WIDE PLUS harvested a lot

The main business of Fujian WIDE PLUS Precision Instrument Co., Ltd. involves the R&D and manufacturing of pressure, flow, temperature, liquid level, photoelectricity, water quality and other parameter sensors as well as instrumentation tubes and valves in the industrial field; the R&D and manufacturing of high-precision automation equipments; high-precision mechanical machining; and the products and overall solutions of the city's intelligent water affairs.

Fujian WIDE PLUS Precision Instrument Co., Ltd.

ADD:No.16, Xingye West Road, Mawei High-tech Zone,Fuzhou,Fujian China

Email:info@wideplus.com

Toll-free technical service number:

400-887-6339

Follow Us On

Copyright © 2023 Fujian WIDE PLUS Precision Instrument Co., Ltd.

闽ICP备05035149号-1 Powered by saa