WIDE PLUS, Fujian Province in 2014 to undertake a major science and technology project in Fujian province, “High-end instrument valves and fittings key technology research and development and industrialization.”

WIDE PLUS, Fujian Province in 2014 to undertake a major science and technology project in Fujian province, “High-end instrument valves and fittings key technology research and development and industrialization.”

(Summary description)Fujian WIDE PLUS Precision Instrument Co. , Ltd. formally undertakes the research of“Key technology r & D and industrialization of high-end instrument valves and fittings”, this project belongs to the development and application of advanced equipment and high-tech, and aims to realize the localization of key components of important technical equipment in national strategic industry.

Moistening instrument valves and fittings not only in the selection of materials on the strict standards and testing means, its unique back sleeve geometry (patented technology) , high reliable double sleeve joint technology, stainless steel corrosion-resistant hardening technology and high reliable long-life sealing technology, the product has a good anti-vibration, anti-impact performance, repeated assembly and disassembly more than 30 times, reaching the international level of leading technology.

WIDE PLUS company will organize and implement major special projects in strict accordance with the interim measures of Fujian province on the administration of major special projects in science and Technology, with the objective of“Strengthening the integration of scientific and technological resources, concentrating on solving key technological problems in economic and social development, promoting the transformation and industrialization of scientific and technological achievements, and training leading scientific and technological personnel in the industry,” Promote the localization of key components of national strategic major technical equipment.

Up-moistening instrument valves and fittings product description:

Material Selection: the standard construction material of the pipe valve is all 316SS stainless steel, the material used has been screened more strictly on the basis of ASTM standard, the performance indexes of intergranular corrosion resistance, pitting corrosion resistance and strength were significantly better than those of conventional 316 stainless steel. The company has complete material composition, strength, corrosion, defects and other inspection equipment and inspection system, all material performance indicators have strict requirements and factory inspection.

Photo of intergranular corrosion

Product design and testing: the structural design of the pipe and valve all pass the international engineering field most authoritative msc. Analysis and optimization of NASTRAN software, design Factor of safety 4:1. All valves have passed a burst test at 4 times the normal operating pressure and a static pressure test at 2 times the normal operating pressure. Each valve passed the sealing test of 7MPA nitrogen pressure.

High Precision Manufacturing: the pipe and valve parts are processed by high precision numerical control processing equipment, which ensures the accuracy of the parts and the consistency of each batch, perfect parts deburring treatment process, key parts of the hardening and corrosion-resistant treatment process, with strict assembly, testing process, to ensure that our products have excellent quality and stability.

- Categories:2015 Year

- Author:

- Origin:

- Time of issue:2015-04-29 08:48

- Views:0

Fujian WIDE PLUS Precision Instrument Co. , Ltd. formally undertakes the research of“Key technology r & D and industrialization of high-end instrument valves and fittings”, this project belongs to the development and application of advanced equipment and high-tech, and aims to realize the localization of key components of important technical equipment in national strategic industry.

Moistening instrument valves and fittings not only in the selection of materials on the strict standards and testing means, its unique back sleeve geometry (patented technology) , high reliable double sleeve joint technology, stainless steel corrosion-resistant hardening technology and high reliable long-life sealing technology, the product has a good anti-vibration, anti-impact performance, repeated assembly and disassembly more than 30 times, reaching the international level of leading technology.

WIDE PLUS company will organize and implement major special projects in strict accordance with the interim measures of Fujian province on the administration of major special projects in science and Technology, with the objective of“Strengthening the integration of scientific and technological resources, concentrating on solving key technological problems in economic and social development, promoting the transformation and industrialization of scientific and technological achievements, and training leading scientific and technological personnel in the industry,” Promote the localization of key components of national strategic major technical equipment.

Up-moistening instrument valves and fittings product description:

Material Selection: the standard construction material of the pipe valve is all 316SS stainless steel, the material used has been screened more strictly on the basis of ASTM standard, the performance indexes of intergranular corrosion resistance, pitting corrosion resistance and strength were significantly better than those of conventional 316 stainless steel. The company has complete material composition, strength, corrosion, defects and other inspection equipment and inspection system, all material performance indicators have strict requirements and factory inspection.

Photo of intergranular corrosion

Product design and testing: the structural design of the pipe and valve all pass the international engineering field most authoritative msc. Analysis and optimization of NASTRAN software, design Factor of safety 4:1. All valves have passed a burst test at 4 times the normal operating pressure and a static pressure test at 2 times the normal operating pressure. Each valve passed the sealing test of 7MPA nitrogen pressure.

High Precision Manufacturing: the pipe and valve parts are processed by high precision numerical control processing equipment, which ensures the accuracy of the parts and the consistency of each batch, perfect parts deburring treatment process, key parts of the hardening and corrosion-resistant treatment process, with strict assembly, testing process, to ensure that our products have excellent quality and stability.

Latest News

Discuss and jointly build | Fujian WIDE PLUS and experts from Northeast Process Automation Design Committee lead the localization process

More services please pay attention to Fujian WIDE PLUS won the Fuzhou Mawei High-tech Park "Harmony Cup" employee tug-of-war invitational third public number

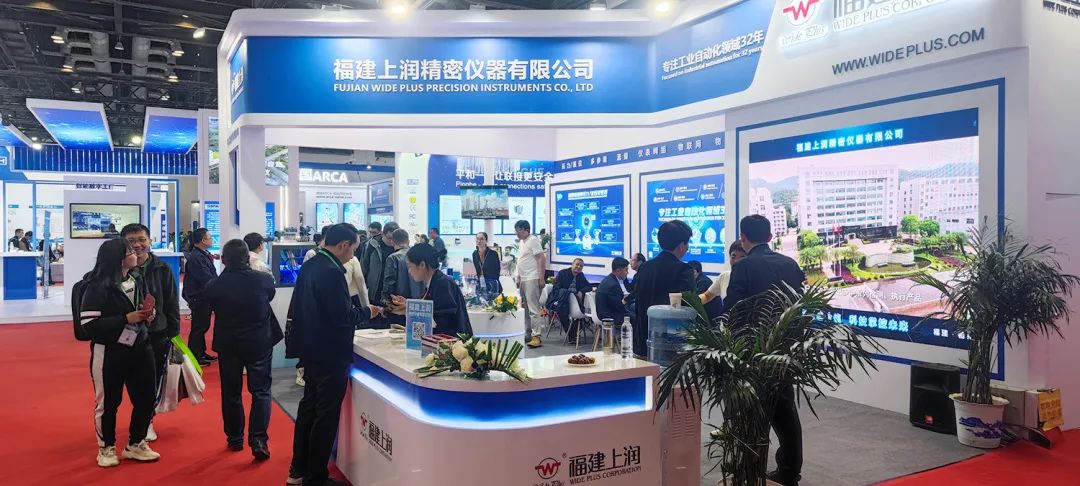

The 31st China International Measurement Control and Instrumentation Exhibition was successfully concluded, and Fujian WIDE PLUS harvested a lot

The main business of Fujian WIDE PLUS Precision Instrument Co., Ltd. involves the R&D and manufacturing of pressure, flow, temperature, liquid level, photoelectricity, water quality and other parameter sensors as well as instrumentation tubes and valves in the industrial field; the R&D and manufacturing of high-precision automation equipments; high-precision mechanical machining; and the products and overall solutions of the city's intelligent water affairs.

Fujian WIDE PLUS Precision Instrument Co., Ltd.

ADD:No.16, Xingye West Road, Mawei High-tech Zone,Fuzhou,Fujian China

Email:info@wideplus.com

Toll-free technical service number:

400-887-6339

Follow Us On

Copyright © 2023 Fujian WIDE PLUS Precision Instrument Co., Ltd.

闽ICP备05035149号-1 Powered by saa