WIDE PLUS high-end instrument valves and pipe fittings key technology development and industrialization successfully passed the project acceptance

WIDE PLUS high-end instrument valves and pipe fittings key technology development and industrialization successfully passed the project acceptance

(Summary description)The major special project of Fujian Province "Development and industrialization of key technologies of high-end instrument valves and pipe fittings" independently undertaken by Fujian WIDE PLUS has successfully completed various research and development tasks of the subject. Recently, the Fujian Science and Technology Department organized experts on the project site acceptance, after listening to the technical report of the research group, financial report, the expert group reviewed the relevant documents and visited the production site, after the defense and serious discussion, the expert group unanimously agreed to pass the subject acceptance.

The project of "Development and industrialization of Key technologies of high-end instrument Valves and pipe fittings" is based on double sleeve joint technology, glow ion carburizing surface hardening technology and high temperature and high pressure seal design technology, and has completed the series design of 12 high-end instrument valves and valves, which has been successfully applied to petroleum, chemical, electric power and other industries. The overall technical level has reached the international first-class level of similar products, breaking the exclusive position of foreign high-end pipe and valve parts in domestic petroleum, petrochemical, nuclear power and other industries, and forming its own brand of high-end pipe and valve parts. During the execution of the project, a total of 5 invention patents and 9 utility model patents were applied, 5 utility model patents were authorized, and 2 academic papers were published. The product indicators fully meet and partially exceed the requirements of the task.

—— Project background ——

As we all know, there are some problems in the instrument pipe and valve industry in our country, such as the pipe and valve enterprises in our country are mainly low-level, small-scale, family-based enterprises. In terms of products, due to the backward design concept, lack of technical investment, low level of manufacturing technology, lack of investment and other reasons, the leading products are still low-quality mass products, there are widespread external leakage, internal leakage, appearance quality is not high, short life, inflexible operation and other shortcomings, some products are only equivalent to the international level in the early 1980s. In the high-end application fields of oil, petrochemical, nuclear power, naval vessels and other pipe and valve parts, the internal leakage of pipe and valve parts will seriously affect the measurement accuracy of precision instruments, small external leakage may lead to catastrophic accidents, and the corrosion of the conveyed medium affects the life of pipe and valve parts, leakage rate, so these industries without exception require the use of high-reliability high-end pipe and valve parts.

—— Upper wetting advantage ——

Drawing on the development experience of Germany and Japan's high-end manufacturing industry, WIDE PLUS has long adhered to high-precision mechatronics manufacturing technology as the basis. Through unremitting efforts, both precision processing equipment and precision processing technology have formed a complete set of high-precision manufacturing technology systems, laying the foundation for promoting mechatronics manufacturing to a higher level of development. At the same time, it also creates a high-precision manufacturing technology discipline of "multi-coordinate interactive positioning". And the company has a variety of precision and ultra-precision machine tool equipment, such as 5-axis linkage machining center, CNC universal machining center, high-speed CNC horizontal machining center and other equipment from Germany, Japan and the United States, the processing accuracy can reach 100 nanometers.

—— Project advantages and characteristics ——

Our pipe and valve parts project has unique advantages, has established a high-end pipe and valve parts of their own brand, successfully broke the foreign industry technology monopoly position:

1、High reliability bushing joint technology: design a new type of double bushing joint, using metal to metal sealing pair design and test; Compensatory seal structure design; Very low leakage valve seat soft seal design; Very low leakage valve port hard seal design, so that the product to achieve zero leakage, but also repeatedly disassembled more than 30 times to maintain high sealing reliability.

2、The use of unique austenitic stainless steel corrosion resistance surface hardening technology, enhance the surface hardness (≥65HRC) and corrosion resistance (surface pitting potential ≥500mV), to meet the high temperature and high pressure high corrosion environment;

3、Based on finite element analysis technology, the valve structure is designed more optimally.

4、At the same time, we test and evaluate the reliability of pipe and valve parts: including the research

- Categories:2018 Year

- Author:

- Origin:

- Time of issue:2018-07-27 13:47

- Views:0

—— Project outcome ——

The major special project of Fujian Province "Development and industrialization of key technologies of high-end instrument valves and pipe fittings" independently undertaken by Fujian WIDE PLUS has successfully completed various research and development tasks of the subject. Recently, the Fujian Science and Technology Department organized experts on the project site acceptance, after listening to the technical report of the research group, financial report, the expert group reviewed the relevant documents and visited the production site, after the defense and serious discussion, the expert group unanimously agreed to pass the subject acceptance.

The project of "Development and industrialization of Key technologies of high-end instrument Valves and pipe fittings" is based on double sleeve joint technology, glow ion carburizing surface hardening technology and high temperature and high pressure seal design technology, and has completed the series design of 12 high-end instrument valves and valves, which has been successfully applied to petroleum, chemical, electric power and other industries. The overall technical level has reached the international first-class level of similar products, breaking the exclusive position of foreign high-end pipe and valve parts in domestic petroleum, petrochemical, nuclear power and other industries, and forming its own brand of high-end pipe and valve parts. During the execution of the project, a total of 5 invention patents and 9 utility model patents were applied, 5 utility model patents were authorized, and 2 academic papers were published. The product indicators fully meet and partially exceed the requirements of the task.

—— Project background ——

As we all know, there are some problems in the instrument pipe and valve industry in our country, such as the pipe and valve enterprises in our country are mainly low-level, small-scale, family-based enterprises. In terms of products, due to the backward design concept, lack of technical investment, low level of manufacturing technology, lack of investment and other reasons, the leading products are still low-quality mass products, there are widespread external leakage, internal leakage, appearance quality is not high, short life, inflexible operation and other shortcomings, some products are only equivalent to the international level in the early 1980s. In the high-end application fields of oil, petrochemical, nuclear power, naval vessels and other pipe and valve parts, the internal leakage of pipe and valve parts will seriously affect the measurement accuracy of precision instruments, small external leakage may lead to catastrophic accidents, and the corrosion of the conveyed medium affects the life of pipe and valve parts, leakage rate, so these industries without exception require the use of high-reliability high-end pipe and valve parts.

—— Upper wetting advantage ——

Drawing on the development experience of Germany and Japan's high-end manufacturing industry, WIDE PLUS has long adhered to high-precision mechatronics manufacturing technology as the basis. Through unremitting efforts, both precision processing equipment and precision processing technology have formed a complete set of high-precision manufacturing technology systems, laying the foundation for promoting mechatronics manufacturing to a higher level of development. At the same time, it also creates a high-precision manufacturing technology discipline of "multi-coordinate interactive positioning". And the company has a variety of precision and ultra-precision machine tool equipment, such as 5-axis linkage machining center, CNC universal machining center, high-speed CNC horizontal machining center and other equipment from Germany, Japan and the United States, the processing accuracy can reach 100 nanometers.

—— Project advantages and characteristics ——

Our pipe and valve parts project has unique advantages, has established a high-end pipe and valve parts of their own brand, successfully broke the foreign industry technology monopoly position:

1、High reliability bushing joint technology: design a new type of double bushing joint, using metal to metal sealing pair design and test; Compensatory seal structure design; Very low leakage valve seat soft seal design; Very low leakage valve port hard seal design, so that the product to achieve zero leakage, but also repeatedly disassembled more than 30 times to maintain high sealing reliability.

2、The use of unique austenitic stainless steel corrosion resistance surface hardening technology, enhance the surface hardness (≥65HRC) and corrosion resistance (surface pitting potential ≥500mV), to meet the high temperature and high pressure high corrosion environment;

3、Based on finite element analysis technology, the valve structure is designed more optimally.

4、At the same time, we test and evaluate the reliability of pipe and valve parts: including the research of test standards for pipe and valve parts, the formulation of enterprise standards for pipe and valve parts, and the comprehensive performance test and evaluation of pipe and valve parts.

5、Industrialization of pipe and valve parts: Based on the company's mature high-precision machine machining technology and a large number of high-end equipment support, the establishment of mass production system, quality assurance system, and high-end production lines matching mass production.

Knowledge popularization:Pipe valve is a small diameter (diameter size is generally less than 50mm) pipe accessories, used to change the channel section and the direction of media flow, control the flow of the conveying medium a device, common instrument valve group, small ball valve, needle valve, plug valve, check valve, pipe joint, etc., commonly used in small and medium-sized test equipment and industrial equipment sampling and measurement and control system. It is used with measuring, analyzing and controlling instruments. It is an indispensable fluid control product for large-scale industrial applications such as petroleum, chemical industry, power station, long-distance pipeline, shipbuilding, nuclear industry, various low-temperature engineering, aerospace and offshore oil production. The quality of pipe and valve parts is closely related to the reliability, measurement and control accuracy of the above applications.

Latest News

Discuss and jointly build | Fujian WIDE PLUS and experts from Northeast Process Automation Design Committee lead the localization process

More services please pay attention to Fujian WIDE PLUS won the Fuzhou Mawei High-tech Park "Harmony Cup" employee tug-of-war invitational third public number

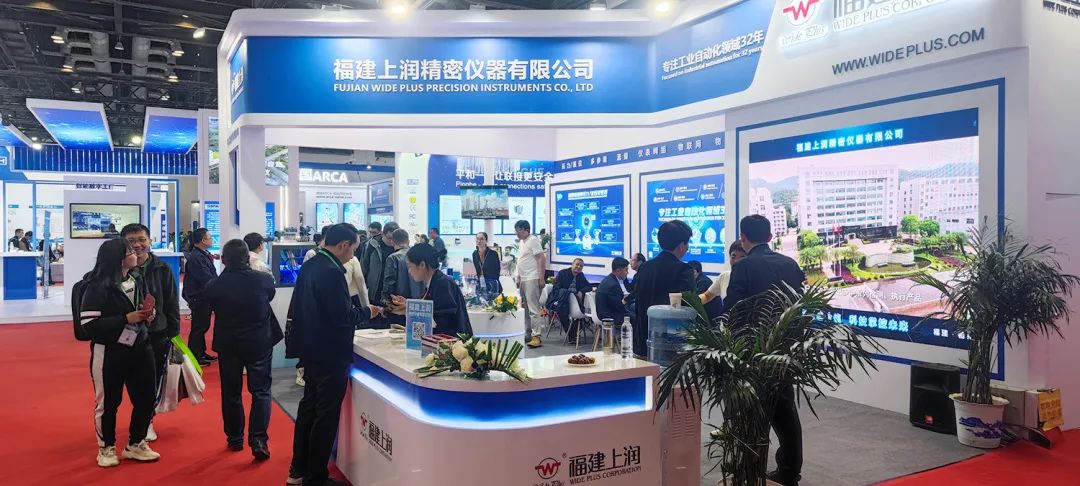

The 31st China International Measurement Control and Instrumentation Exhibition was successfully concluded, and Fujian WIDE PLUS harvested a lot

The main business of Fujian WIDE PLUS Precision Instrument Co., Ltd. involves the R&D and manufacturing of pressure, flow, temperature, liquid level, photoelectricity, water quality and other parameter sensors as well as instrumentation tubes and valves in the industrial field; the R&D and manufacturing of high-precision automation equipments; high-precision mechanical machining; and the products and overall solutions of the city's intelligent water affairs.

Fujian WIDE PLUS Precision Instrument Co., Ltd.

ADD:No.16, Xingye West Road, Mawei High-tech Zone,Fuzhou,Fujian China

Email:info@wideplus.com

Toll-free technical service number:

400-887-6339

Follow Us On

Copyright © 2023 Fujian WIDE PLUS Precision Instrument Co., Ltd.

闽ICP备05035149号-1 Powered by saa