High Precision Manufacturing

The company insists on high precision mechatronics manufacturing technology as the basis, whether it is precision machining equipment, or precision machining process has formed a complete set of high-precision manufacturing technology system, machinery manufacturing technology processing accuracy of 500 nanometers, equipment processing accuracy of 100 nanometers, and has dozens of high, intermediate technicians and a large number of skilled operation of the machine tool and quality control of the technician team is the most complete range of processing varieties of medium and large-scale processing production enterprises in Fujian Province. It is a medium and large-scale processing production enterprise with the most complete processing varieties and wider processing range in Fujian Province.

The company has invested 570 million RMB and imported more than 200 sets of cutting-edge high-precision processing equipments, nearly 100 sets of precision injection molding machines and a series of complete testing instruments and testing equipments from Switzerland, Germany, the U.S., Japan and other countries.

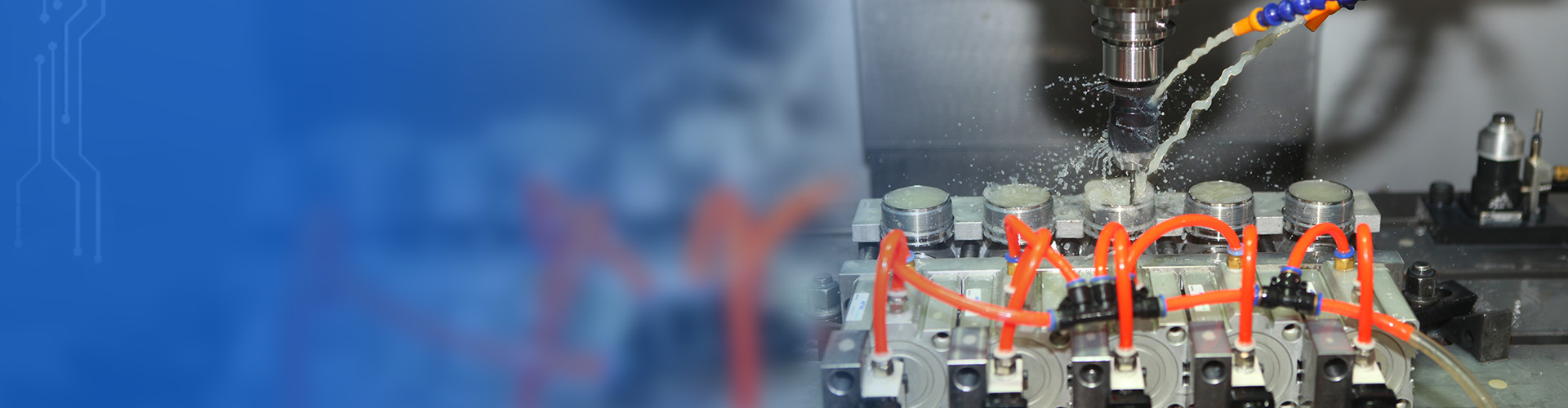

Precision Machining

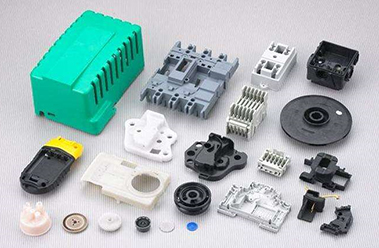

Precision Injection Molding

High-Precision Mold Design And Processing

Main Production Equipment

Nanoscale Internal And External Cylindrical Grinding Machine

Super Precision Coordinate Grinding Machine

Nano-Machining Lathe

Nanoscale Optical Spherical Grinding Machine

Nanometer Surface Grinding Machine

High Precision CNC Lathe

Ultra-Precision Vertical Lathe

Ultra-Precision Vertical/Horizontal Machining Center

Ultra-Precision Five-Axis Machining Center

High precision turning and milling complex machining center

Super precision slow walking wire cutting machine

Ultra-precision EDM machine

Ultra-precision microhole punch

Fanuc precision CNC injection molding machine

Yabao precision CNC injection molding machine

Sumitomo precision CNC injection molding machine

Cylindricity meter

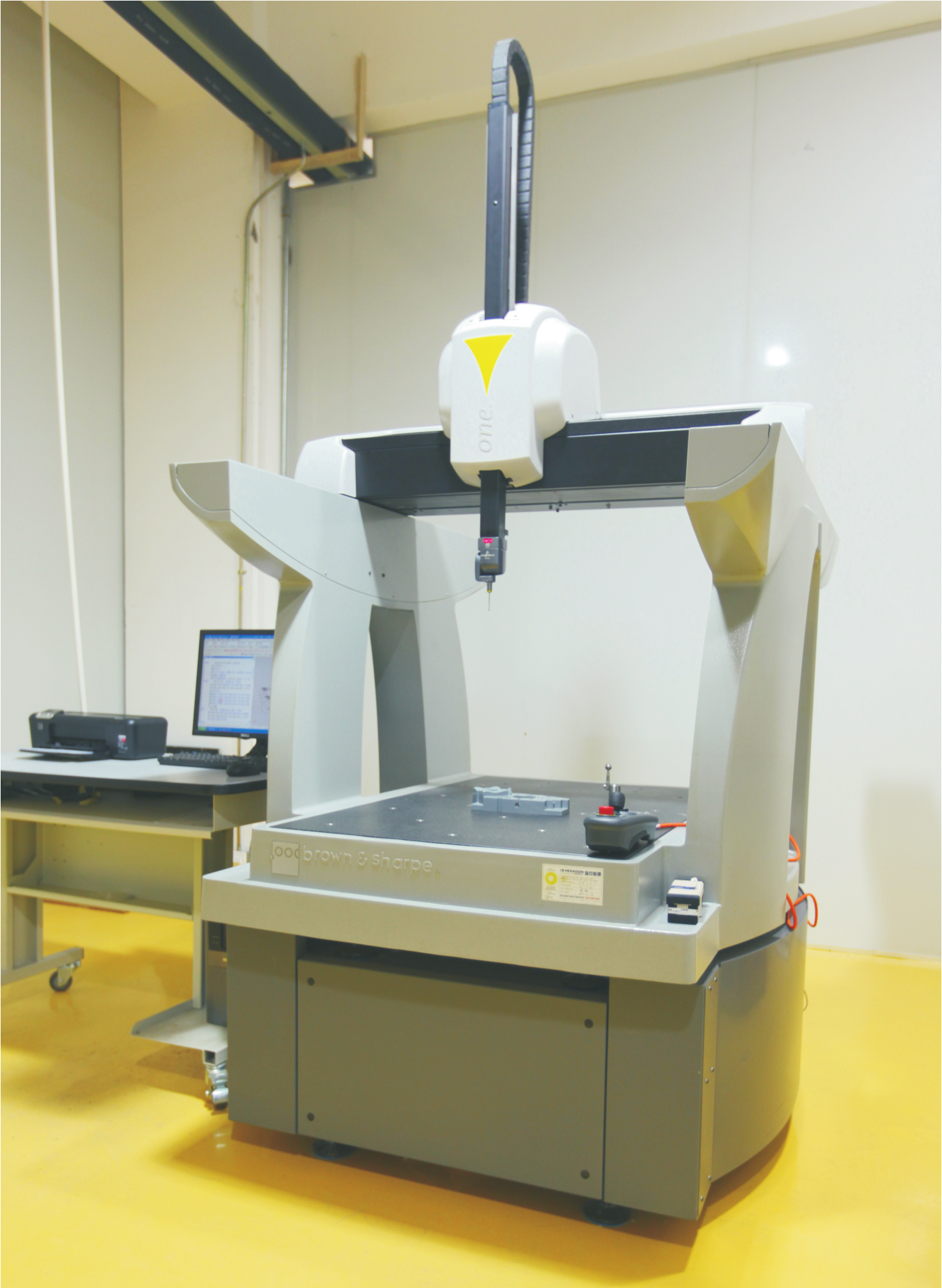

Three coordinate measuring machine

CAE simulation analysis software

Desktop direct reading spectrometer

Ultrasonic flaw detector

Microcomputer control electronic universal testing machine

Metallographic microscope

Universal knife sharpener

projector

The main business of Fujian WIDE PLUS Precision Instrument Co., Ltd. involves the R&D and manufacturing of pressure, flow, temperature, liquid level, photoelectricity, water quality and other parameter sensors as well as instrumentation tubes and valves in the industrial field; the R&D and manufacturing of high-precision automation equipments; high-precision mechanical machining; and the products and overall solutions of the city's intelligent water affairs.

Fujian WIDE PLUS Precision Instrument Co., Ltd.

ADD:No.16, Xingye West Road, Mawei High-tech Zone,Fuzhou,Fujian China

Email:info@wideplus.com

Toll-free technical service number:

400-887-6339

Follow Us On

Copyright © 2023 Fujian WIDE PLUS Precision Instrument Co., Ltd.

闽ICP备05035149号-1 Powered by saa