Walking in the Made in China 2025, high-end manufacturing bathed in spring breeze

Walking in the Made in China 2025, high-end manufacturing bathed in spring breeze

(Summary description)They say finance should serve manufacturing. However, looking back on 2015, we still found that, overall, the most lively or the financial sector, internet finance in full swing, banking performance remains stable, the insurance industry frequently in the market to raise signs.

Manufacturing, by contrast, is a different story. The steel industry is hard to reverse in the short term. Even central government-owned enterprises Baosteel and Wuhan Iron and steel have suffered serious profit declines. Overcapacity industries such as cement and coal have even seen cases of debt defaults. Even the petrochemical industry, from high profit to low profit.

The purchasing managers' Index (PMI) for China's manufacturing sector fell 0.2 percentage points from October to 49.6 in November, according to the latest National Bureau of Statistics of the People's Republic of China of statistics released by the China Federation of Logistics and purchasing, at its lowest point since August 2012, it is below the 50 per cent level for the fourth consecutive month, below the historical average for the same period.

Related experts told reporters that the prosperity index for the fourth consecutive month below the boom-and-bust line, reflecting the decline in China's manufacturing prosperity, economic downward pressure remains severe.

Of course, not all manufacturing sectors are so depressed. Some high-end Made in China 2025, such as robotics (300024 per cent) and large aircraft, are booming.

It is difficult to live with backward production capacity

Industries such as coal and steel, once the pride of Chinese manufacturing, are now synonymous with overcapacity. In 2015, these industries are still struggling to survive.

Representative: Coal, steel

Li, who has worked with his parents in the coal business, still remembers their“Golden decade”. “It's very simple. Just buy a mine, buy coal equipment, and then open up the coal transportation chain. Then you will have buckets of 'gold' waiting for you,” Li previously told the International Financial Times.

But since June 2012, coal prices into the downward channel, announced the end of the coal market“Golden Decade”, coal enterprises into the loss channel.

In 2015, the situation is worsening, with the possibility of more than just losses, but also a previously unthinkable debt default.

On November 4th Hengding Industrial International Development, a Hong kong-listed company that is the biggest coal producer in Sichuan, announced it was defaulting on its debt. The company said it had about $190.6 m of outstanding principal and $7.9 m of accrued interest due.

In the eyes of some in the industry, Hengding may be a microcosm of China's coal industry. Because according to an earlier survey by the China Coal Industry Association, “At present, except for a few advantageous enterprises and some listed companies, most other coal enterprises in China have already lost money. Moreover, because of the serious losses, the shortage of capital chain of coal enterprises has become more and more prominent, and the phenomenon of coal mines reducing wages and defaulting on wages has become more and more common.”

China debt capital said that the geological conditions of coal enterprises in Sichuan, Guizhou and other places are more complicated, and production costs as a whole are at a higher level in the industry, “In the first half of 2015, the southwest region as a whole posted losses in bond issuance. Among them, the credit risks of Yuncoal and Sichuan coal industry groups are particularly prominent, and investors need to pay close attention to them.”.

“In the short term, the coal industry will continue to operate at a low level, and the overall credit risk of the coal industry will increase,” China credit said. “The default of Hengding may further increase the credit risk premium of coal enterprises.”

“Coal prices will continue to fall in the future. This means there are likely to be more cases of debt defaults. Even some companies, including large ones, may fail.” A number of experts and industry insiders in an interview with reporters frankly.

The situation in the steel industry is also not encouraging. From 2014 onwards, China's steel enterprise bankruptcy has emerged, 2015, bankruptcy more frequent.

Since March 18 this year, the Steel Enterprises, once ranked as one of the four largest private steel companies, stopped production completely, opening the prelude to the bankruptcy of Steel Enterprises this year, and several steel enterprises have joined the“Bankruptcy” echelon one after another, and these steel enterprises were one of the local leading enterprises in the industry. The capital chain breaks, becomes these steel enterprise most lethal wound.

CISA statistics show that the total asset-liability ratio of China's steel enterprises has been close to 70% , key steel enterprises, many enterprises in the debt ratio of more than 90% . Miao

- Categories:2016 Year

- Author:

- Origin:

- Time of issue:2016-05-31 15:33

- Views:0

They say finance should serve manufacturing. However, looking back on 2015, we still found that, overall, the most lively or the financial sector, internet finance in full swing, banking performance remains stable, the insurance industry frequently in the market to raise signs.

Manufacturing, by contrast, is a different story. The steel industry is hard to reverse in the short term. Even central government-owned enterprises Baosteel and Wuhan Iron and steel have suffered serious profit declines. Overcapacity industries such as cement and coal have even seen cases of debt defaults. Even the petrochemical industry, from high profit to low profit.

The purchasing managers' Index (PMI) for China's manufacturing sector fell 0.2 percentage points from October to 49.6 in November, according to the latest National Bureau of Statistics of the People's Republic of China of statistics released by the China Federation of Logistics and purchasing, at its lowest point since August 2012, it is below the 50 per cent level for the fourth consecutive month, below the historical average for the same period.

Related experts told reporters that the prosperity index for the fourth consecutive month below the boom-and-bust line, reflecting the decline in China's manufacturing prosperity, economic downward pressure remains severe.

Of course, not all manufacturing sectors are so depressed. Some high-end Made in China 2025, such as robotics (300024 per cent) and large aircraft, are booming.

It is difficult to live with backward production capacity

Industries such as coal and steel, once the pride of Chinese manufacturing, are now synonymous with overcapacity. In 2015, these industries are still struggling to survive.

Representative: Coal, steel

Li, who has worked with his parents in the coal business, still remembers their“Golden decade”. “It's very simple. Just buy a mine, buy coal equipment, and then open up the coal transportation chain. Then you will have buckets of 'gold' waiting for you,” Li previously told the International Financial Times.

But since June 2012, coal prices into the downward channel, announced the end of the coal market“Golden Decade”, coal enterprises into the loss channel.

In 2015, the situation is worsening, with the possibility of more than just losses, but also a previously unthinkable debt default.

On November 4th Hengding Industrial International Development, a Hong kong-listed company that is the biggest coal producer in Sichuan, announced it was defaulting on its debt. The company said it had about $190.6 m of outstanding principal and $7.9 m of accrued interest due.

In the eyes of some in the industry, Hengding may be a microcosm of China's coal industry. Because according to an earlier survey by the China Coal Industry Association, “At present, except for a few advantageous enterprises and some listed companies, most other coal enterprises in China have already lost money. Moreover, because of the serious losses, the shortage of capital chain of coal enterprises has become more and more prominent, and the phenomenon of coal mines reducing wages and defaulting on wages has become more and more common.”

China debt capital said that the geological conditions of coal enterprises in Sichuan, Guizhou and other places are more complicated, and production costs as a whole are at a higher level in the industry, “In the first half of 2015, the southwest region as a whole posted losses in bond issuance. Among them, the credit risks of Yuncoal and Sichuan coal industry groups are particularly prominent, and investors need to pay close attention to them.”.

“In the short term, the coal industry will continue to operate at a low level, and the overall credit risk of the coal industry will increase,” China credit said. “The default of Hengding may further increase the credit risk premium of coal enterprises.”

“Coal prices will continue to fall in the future. This means there are likely to be more cases of debt defaults. Even some companies, including large ones, may fail.” A number of experts and industry insiders in an interview with reporters frankly.

The situation in the steel industry is also not encouraging. From 2014 onwards, China's steel enterprise bankruptcy has emerged, 2015, bankruptcy more frequent.

Since March 18 this year, the Steel Enterprises, once ranked as one of the four largest private steel companies, stopped production completely, opening the prelude to the bankruptcy of Steel Enterprises this year, and several steel enterprises have joined the“Bankruptcy” echelon one after another, and these steel enterprises were one of the local leading enterprises in the industry. The capital chain breaks, becomes these steel enterprise most lethal wound.

CISA statistics show that the total asset-liability ratio of China's steel enterprises has been close to 70% , key steel enterprises, many enterprises in the debt ratio of more than 90% . Miao changxing, deputy director-general of the Policy Department of the Ministry of Industry and Information Technology, said the total debt of China's steel industry is about 3 trillion yuan.

Li Xinchuang, president of the Institute of Metallurgical Industry Planning and research, pointed out that 2015 is a major turning point for China's steel industry, which has entered the stage of reduction development. China's steel demand is expected to fall 4.8 percent this year and 3 percent next year to 668 million tons and 648 million tons, according to the metallurgical industry planning and Research Institute.

Wang Jianhua, Chief Steel Analyst at Shanghai Steel Union (300226 per cent) , believes the current steel industry has really entered a downturn. There are many factors contributing to the downturn. For example, raw material prices in the upper reaches have fallen more than steel prices, and steel mills are making even bigger profits and losses. Supply-side contraction is smaller than demand-side contraction, it is also the reason why prices continue to fall sharply. “All in all, the downturn in steel companies has just begun and there is still room for steel prices to fall by 5-10 per cent for a long time to come.”.

The“Iron Rice Bowl” industry is in decline

Many industries, such as oil and petrochemicals, are regarded as“Iron rice bowls” and“Sit and collect money”. However, with the changes in domestic and foreign macro-economic environment and consumption environment, these industries have shown signs of decline.

Representative: Petroleum and petrochemical

Speaking of the“Iron rice bowl” in the industry, oil and petrochemical industry should be everyone's eyes of the“Windfall profits” industry, but from the“Three barrels of oil” performance this year, are not satisfactory, “Windfall profits” have shrunk a lot.

Sinopec's third-quarter results showed that its operating income in the first nine months was 1.536837 trillion yuan, down 27.36 percent from the same period last year. Net profit attributable to shareholders of the parent company was 25.848 billion yuan, down 49.49 percent from the same period last year.

At the same time, Petrochina's third-quarter results showed that the company's turnover was 1.305105 trillion yuan, down 25.6 percent from the same period last year. Net profit attributable to the company's shareholders was 30.601 billion yuan, or 0.17 yuan per share, it was down 68.1 per cent year-on-year.

After the Earnings Report, CNPC said the devaluation of the Renminbi was good for the company, with the company earning 1 billion yuan for every percentage point devaluation of the renminbi. An asset swap could be announced soon. If oil prices remain low, capital spending will be cut further.

International oil prices have fallen nearly 55% since the middle of last year. Global oil prices have been hovering in a depressed state due to the Fed's interest rate hike, the continued strength of the US dollar, record OPEC production capacity, slowing world economic growth and supply seriously exceeding demand.

Lee Eon, an analyst at Longzhong, said the drop in oil prices was so low because signs of deterioration on the demand side had clearly outweighed the impact of the oversupply.

Petrochina said that in the fourth quarter, the international oil price volatility pattern is difficult to change, the domestic oil and gas market in general over-supply, production and marketing contradictions, and other problems can not be fundamentally alleviated.

As CNPC said, the fourth quarter oil prices are still not optimistic, it is likely to face a more severe situation.

Zhongyu information analysis said, “The surge in international crude oil inventories of the endless news, the global supply of excess crude oil concerns continue to increase, oil prices still have downside risks.”

The industry generally believes that if the demand side of the future difficult to boost, oil prices will be more difficult to rebound, the United States and OPEC to maintain high production, abundant supply in the near term there is little hope of reversal, the pattern of oversupply can not support the rise of trend. At the same time, fed rate expectations are still in doubt, the strong dollar is on the side of the tiger, and the days of low oil prices are likely to continue for a long time, which will lead to“Three barrels of oil” days continue to be difficult and difficult to improve.

Policies boost new energy

Although some industries have unlimited prospects, but in recent years frequent setbacks due to various factors, with the introduction of relevant domestic policies, they gradually out of the haze.

Representative: photovoltaic

PV is clearly typical. Solar power is a clean energy source that has been growing rapidly, but China's export-oriented solar sector has been hit hard by repeated anti-solar investigations from Europe and the US.

However, it is gratifying to note that with strengthened policy support and the continuous launch of the domestic market, China's photovoltaic industry has gradually come out of its low point and continued its rapid development, photovoltaic power plants gain market expansion opportunities.

“By 2020, the target for solar power generation has been raised by 50% to 150 GW from the previous 100 GW,” he said at the 2015 China Photovoltaic Conference and exhibition on October 13, dong Xiufen, director of the New Energy Department of the National Energy Administration's Department of New Energy and renewable energy, said.

To reverse this target, the 13th five-year plan period needs to add about 20 million kilowatts of new photovoltaic capacity each year, significantly higher than the previous average level.

Not long ago, the National Energy Administration also issued a notice on increasing the construction scale of photovoltaic power plants in some regions in 2015(hereinafter referred to as the notice) , a total of 5.3 million kilowatts (5.3 GW) of photovoltaic power plants will be built nationwide. The increase is a 30% increase on the 17.8 gigawatts of new installed capacity announced by the National Energy Administration in 2015. This is undoubtedly on the road to recovery of the photovoltaic industry gave a shot in the arm.

In an interview with the International Financial Times, the solar companies all said that this year, under the promotion of the policy, the solar PV installed capacity continued to grow significantly, and the recovery of the industry is obvious.

Figures from Gao Jifan, chairman of Trina Solar and chairman of the China Photovoltaic Industry Association, show that new installed capacity reached 10.5 GW in the first three quarters of this year, the same as in the whole of last year.

Xu Tian, general manager of huibao, said: “First, for photovoltaic manufacturers, it is a sign of a new wave of orders in the fourth quarter of this year, which will undoubtedly inject a shot into the heart of the industry. Second, it means that the project initiation, construction and income period are brought forward, and projects that did not have the opportunity to be initiated this year will probably be approved and put into development and construction.”, the scale of the installation may trigger a new wave of investment in photovoltaic projects.

Qian Jing, Jinke's spokesperson, told reporters that in the first half of 2015, domestic industrial value-added growth was below GDP growth, and the downward pressure on economic growth was indeed great, but only the photovoltaic industry bucked the trend. In the first half of 2015, grid-connected capacity was 7.73 GW, more than double the 3.32 GW in the first half of 2014. And the PV industry installation peak often in the second half of the year, so this year is expected to install more than 17.8 GW in China, to reach a record high of 20 GW.

“With such a large installation volume, it can be said that China's solar market has ushered in an unprecedented boom,” said Qian.

Apart from increasing installed capacity, the implementation of the “Belt and Road” strategy has also opened up new directions for the Chinese PV industry to “Go global”.

Chen Kangping, Jinko president, told reporters that Jinko is deploying and implementing its strategy of“Going global”, from global sales to global manufacturing, and eventually as the process of internationalisation intensifies, plan to achieve global investment.

According to the briefing, Jinko Energy has launched a global manufacturing program in countries other than China, and has now opened battery module factories in South Africa and Portugal. The company is investing in a third overseas plant in Southeast Asia.

High-end manufacturing in the Spring Breeze

As we all know, China's manufacturing industry is in transition. Against the backdrop of a new normal for the economy, the Chinese proposed a “Made in China 2025 plan” in May that, in the view of analysts, “Made in China 2025” is similar to the German “Industry 4.0 strategy”.

In the “Made in China 2025” planning, intelligent manufacturing is positioned as the main direction of Chinese manufacturing. And intelligent manufacturing, including robotics, has become a hot industry for enterprises and capital.

Delegate: Robot, unmanned vehicle

How Hot are the robots? In early November, the annual China International Industry Expo was a case in point.

The reporter learned from the exhibitors that they are optimistic about the huge potential of the Chinese domestic market such as “Industry 4.0” and “Made in China 2025”.

“I have lived and worked in many places, including the US, Europe, Italy and Thailand, but it is China that fascinates me most. China has become the largest robotics market in the world and there is huge potential in this market,” Matthias, Holy Roman Emperor Viceland, chief operating officer of Comau's global robotics division, told the International Financial Times.

Matthias, Holy Roman Emperor Wickland gives concrete figures to back up the claim that the average manufacturing worker in China has 30 robots for every 10,000 workers, compared with more than 300 in South Korea and Japan, therefore, the future development potential is very big.

“I have now moved my entire family to China, and this is a long-term decision for me, precisely because I value the development of this market and want to invest more to help Comau in the long-term development of the Chinese market,” Matthias, Holy Roman Emperor Viceland said.

Jayson Patton, Chief Revenue Officer, told the Financial Times that Rethink Robotics was expanding globally and that the Chinese market was a cornerstone of its global expansion plans, china is expected to be the company's biggest market within a year.

Although it is just starting, China's robot market has become the world's largest, and the market demand is rising. In 2015, shipments of ABB, fanaco, Yaskawa Electric and Kuka in the Chinese market all grew by about 25 percent, according to the Institute of robotics research.

From the policy point of view, China's robot industry has indeed stood in the industrial development“Wind.”.

The reporter learned that before this, all over the country from finance, tax and financing to reduce the burden on enterprises, promote the implementation of enterprises“Machine replacement”, in order to promote the upgrading of manufacturing industry and even the upgrading of regional economic transformation. Hangzhou, for example, “Will provide 25 per cent of the cost of the Internet of things (the main form of“Machine Replacement”) project to enterprises that implement the project”.

The State Administration of Work Safety has announced a plan to replace people mechanically and reduce them automatically by the end of June 2018, the voice of China News and newspaper digest reported, will realize high-risk workplace operators to reduce more than 30% .

Analysts at Guosen Securities (002736) said that policies to boost the growth of warm air-powered robots range from “Made in China 2025” in this year's government report to documents issued by various ministries to promote the development of the robot industry, at the same time, local governments have invested heavily, the number of domestic industrial parks has climbed to a new high, and the robot industry has a bright future.

Driverless cars are also hot this year. After watching a demonstration of Baidu's driverless car technology at the Internet Conference, the President recently mentioned driverless car innovation again in his unscripted speech at the central economic work conference. Analysts say this is enough to show that driverless cars are getting a lot of attention.

At present, there are many enterprises have been or are preparing to enter the unmanned vehicle market. On December 19, at the zero annual meeting of Peking University's Guanghua New Year Forum, Liu Wei, who is travelling from Didi, said that Didi would work to build a self-driving vehicle system with its own intellectual property rights, and will soon announce plans for driverless cars. He did not say when.

On June 4 this year, Didi Kuaidi formally signed a strategic cooperation agreement with BAIC, and the two sides will conduct in-depth cooperation in four major areas, including autonomous vehicles, new energy vehicles, vehicle networking, and enterprise vehicles.

In early December, Baidu successfully completed road tests of its self-driving car hybrids, and on December 14, Baidu announced the formal establishment of its autonomous driving division. Wang Jin, senior vice-president of Baidu, is general manager of the division.

Wang Jin pointed out that in the past, the value of the car mainly in the engine, gearbox and other mechanical equipment, in the future, its value will be more reflected in the intelligent system. In the future, cars will be fully self-driving, controlled by intelligent systems. In the next decade, he predicts, 80 per cent of new cars will be self-driving. Baidu's target is for commercial use in the next three years and mass production in five.

Xu Changming, director of the Information Resources Development Department of the National Information Center, is confident about the future of autonomous driving and smart travel: “Autonomous driving is a major development direction of the automobile industry and an important foundation for realizing smart transportation and smart cities in the future.”

The report estimates that the penetration rate of internet-based vehicles will exceed 10% in 2015, and the market size will exceed 100 billion yuan. In recent years, major global automobile enterprise groups have continued to increase their investment in technology research and development and demonstration operations, the global auto industry spent about $10bn on autonomous driving in 2010, rising to $160BN by 2016. Driverless cars could be the next blue sea for China's economy.

Latest News

Discuss and jointly build | Fujian WIDE PLUS and experts from Northeast Process Automation Design Committee lead the localization process

More services please pay attention to Fujian WIDE PLUS won the Fuzhou Mawei High-tech Park "Harmony Cup" employee tug-of-war invitational third public number

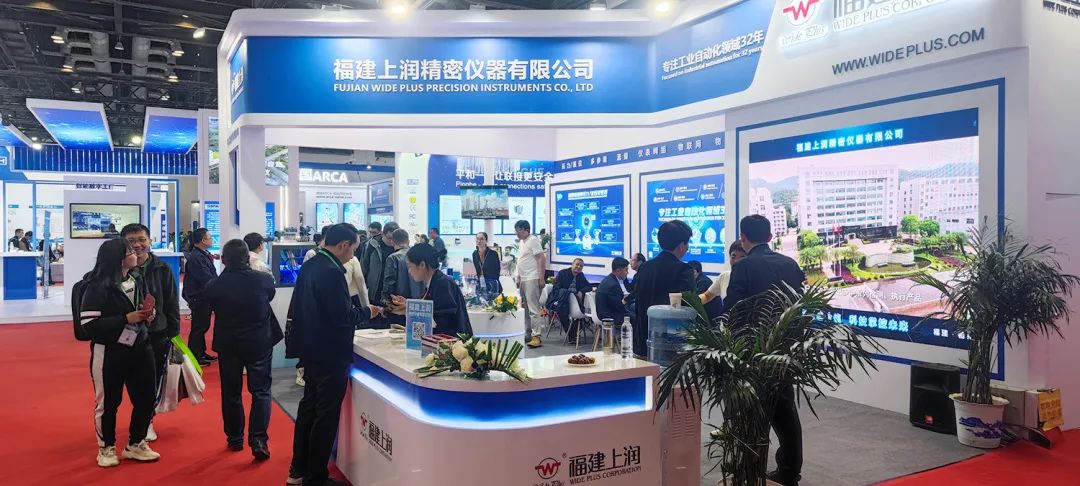

The 31st China International Measurement Control and Instrumentation Exhibition was successfully concluded, and Fujian WIDE PLUS harvested a lot

The main business of Fujian WIDE PLUS Precision Instrument Co., Ltd. involves the R&D and manufacturing of pressure, flow, temperature, liquid level, photoelectricity, water quality and other parameter sensors as well as instrumentation tubes and valves in the industrial field; the R&D and manufacturing of high-precision automation equipments; high-precision mechanical machining; and the products and overall solutions of the city's intelligent water affairs.

Fujian WIDE PLUS Precision Instrument Co., Ltd.

ADD:No.16, Xingye West Road, Mawei High-tech Zone,Fuzhou,Fujian China

Email:info@wideplus.com

Toll-free technical service number:

400-887-6339

Follow Us On

Copyright © 2023 Fujian WIDE PLUS Precision Instrument Co., Ltd.

闽ICP备05035149号-1 Powered by saa