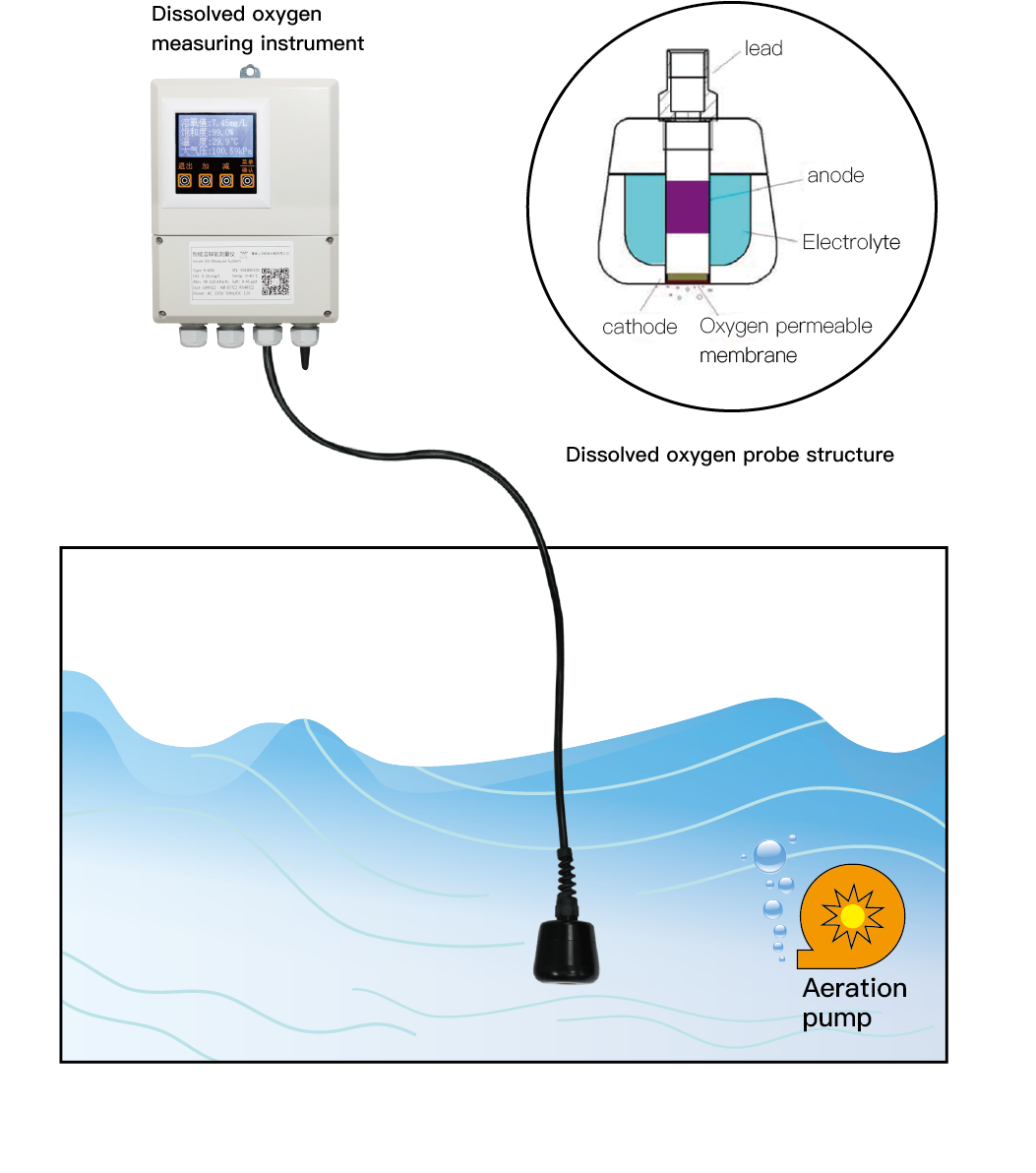

The intelligent wireless dissolved oxygen measuring instrument uses a galvanic oxygen sensor to monitor the dissolved oxygen concentration in water, and is mainly used for real-time online measurement in places such as breeding and water quality monitoring. The system takes micro-processing as the core and has self-calibration and compensation functions of temperature, atmospheric pressure and salinity. It has accurate measurement, fast response speed, good stability and can work reliably for a long time. The system uses NB-IoT wireless wide area network communication technology, and the data is sent to the cloud platform through the Internet of Things. It also displays information such as dissolved oxygen, water temperature, and local atmospheric pressure, making the system convenient and fast to use.

Advantages

- Quick response

- Sensor probe waterproof design

- LCD large screen display operation is simple and fast

- Good stability, can work reliably for a long time

- Dissolved oxygen concentration difference alarm

Technical index

- Dissolved oxygen: 0~20mg/l ±0.5mg/l

- Resolution: 0.1mg/l

- Saturation: 0~200%

- Temperature: 0-60℃ ±0.5℃

- Atmospheric pressure: 90-110 kPa(A)

- Salinity compensation: 0-59 PPT (g/kg)

- Response time: 60s

- Communication method: NB-IoT wide area network data transmission

- Power supply: AC220V 50Hz

- Installation method: sensor-field input, display-wall-mounted and panel-mounted

Sales Contact

Meter Sales Inquiry(TEL):0591-83969820

Email:info@wideplus.com

Toll Free Technical Service: 400-887-6339

The main business of Fujian WIDE PLUS Precision Instrument Co., Ltd. involves the R&D and manufacturing of pressure, flow, temperature, liquid level, photoelectricity, water quality and other parameter sensors as well as instrumentation tubes and valves in the industrial field; the R&D and manufacturing of high-precision automation equipments; high-precision mechanical machining; and the products and overall solutions of the city's intelligent water affairs.

Fujian WIDE PLUS Precision Instrument Co., Ltd.

ADD:No.16, Xingye West Road, Mawei High-tech Zone,Fuzhou,Fujian China

Email:info@wideplus.com

Toll-free technical service number:

400-887-6339

Follow Us On

Copyright © 2023 Fujian WIDE PLUS Precision Instrument Co., Ltd.

闽ICP备05035149号-1 Powered by saa